Product Line

Extending tool life for the lumber industry.

Lubie® 1000 Spray System

The rugged Biolube spray system is specifically designed for Lubie® products only. Its reliable and cost-effective applicator accurately atomizes the correct formula of lubricant onto wood or metal processing blades and tooling.

Customers report longer blade and tool life along with reduced downtime. Filer's spend less time cleaning and sharpening blades. Simply install the nozzles, connect your air supply and the spray system is operational. Lube flow is quickly and easily adjusted.

The rugged Biolube spray system is specifically designed for Lubie® products only. Its reliable and cost-effective applicator accurately atomizes the correct formula of lubricant onto wood or metal processing blades and tooling.

Customers report longer blade and tool life along with reduced downtime. Filer's spend less time cleaning and sharpening blades. Simply install the nozzles, connect your air supply and the spray system is operational. Lube flow is quickly and easily adjusted.

Lubie® Lubes

Lubie® lubricants are formulated for specific uses to meet your particular need. Our lubricants are proven to be trouble-free and are biodegradable. No silicones or waxes are used in any of our products and most are free of toxic or hazardous chemicals. Lubie® lubricants are easily applied using the low-maintenance Lubie® LubeMaster Spray System.

Lubie® lubricants are formulated for specific uses to meet your particular need. Our lubricants are proven to be trouble-free and are biodegradable. No silicones or waxes are used in any of our products and most are free of toxic or hazardous chemicals. Lubie® lubricants are easily applied using the low-maintenance Lubie® LubeMaster Spray System.

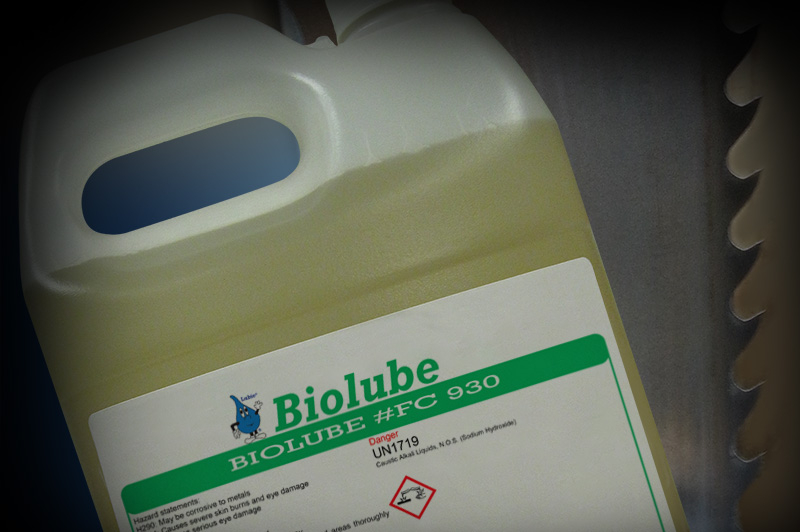

Grinding Coolants

Our coolants are formulated for all types of manual and automatic grinding and machining operations. They are commonly used with high speed steel, carbide or coated carbide tooling. Economical and resistant to bacterial growth, these coolants have excellent water dilution rates, resist cobalt leaching, provide effective corrosion and rust protection extending tool life.

Our coolants are formulated for all types of manual and automatic grinding and machining operations. They are commonly used with high speed steel, carbide or coated carbide tooling. Economical and resistant to bacterial growth, these coolants have excellent water dilution rates, resist cobalt leaching, provide effective corrosion and rust protection extending tool life.

Blade & Pitch Cleaners

Our cleaners are formulated for various needs in cleaning pitch, tar, and resin build up within machining operations. Our products are effective, economical and developed for longer blade and tool life ensuring less time spent on cleanup.

Our cleaners are formulated for various needs in cleaning pitch, tar, and resin build up within machining operations. Our products are effective, economical and developed for longer blade and tool life ensuring less time spent on cleanup.